Choosing the right chainsaw chain type: A step-by-step guide

If you want to get the most out of your chainsaw, it’s important that you choose the right chainsaw chain. Here is a step-by-step guide which helps you pick the right chainsaw chain type.

If you want to get the most out of your chainsaw, it’s important that you choose the right chainsaw chain. Here is a step-by-step guide which helps you pick the right chainsaw chain type.

Get the basics right

For those who are new to chainsaw chains, begin by reading our step-by-step guide to understand key components like pitch, gauge, drive links, and cutter designs. If you already have a grasp of the basics, click on our Bars & Chains Guide below to find the right chainsaw chain for your Husqvarna chainsaw.

Step 1: Pitch, Gauge, and Number of Drive Links

When choosing a chainsaw chain, you first need to know the pitch, the gauge and the number of drive links. Once you have these, everything else about the choice is basically about what you prefer.

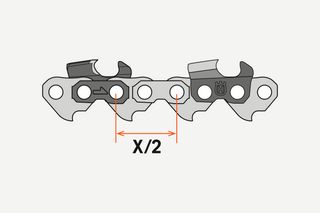

- Pitch refers to the average distance between two rivets on the saw chain. It is commonly displayed on the guide bar with values like 1/4", .325", 3/8", or .404". If you're unable to locate the pitch, we recommend having your dealer measure your old chainsaw chain, as it can be tricky to determine accurately.

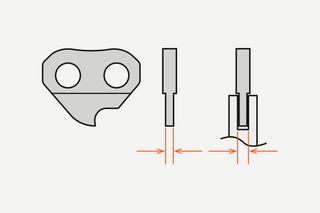

- Gauge indicates the thickness of the drive links and is crucial for ensuring proper fitting into the guide bar. Common gauge values include .043", .050", .058", or .063". Like pitch, gauge is usually displayed on the guide bar. If not, consult a dealer to measure the gauge on your old chainsaw chain.

- The length of a chainsaw chain is determined by the pitch and the number of drive links. This information is not typically printed on the bar or anywhere else on the product. Therefore, it's necessary to count the links on the old chainsaw chain when determining the length.

Step 2: Full Chisel, Semi-Chisel, and Chipper Chains

Modern saw chains come in three basic cutter designs: full chisel, semi-chisel, and chipper.

- Full chisel saw chains have sharp cutter corners that efficiently split wood fibers. They provide the fastest and most efficient cutting experience in clean softwood.

- Semi-chisel saw chains have slightly rounded cutter corners. This design enables the cutter to retain sharpness for longer periods, particularly when cutting hard or frozen wood or working in dirty surroundings. In such conditions, a full chisel saw chain would quickly lose its sharpness.

- Chipper saw chains share similarities with semi-chisel chains but have an even rounder working corner.

Step 3: Matching teeth and muscles

Putting a heavy-duty saw chain type on a standard chainsaw will not give you a better performance. It is like putting shark teeth on a piranha – the bite will not get any better.

By selecting the appropriate combination, your cutting equipment will consistently deliver maximum performance.

To find a saw chain that exactly matches your chainsaw, try out the Husqvarna Bars & Chains Guide.

X-CUT® and X-Precision™ chains features explained

Explore the reasoning behind X-CUT and X-Precision chains' features with helpful illustrations.

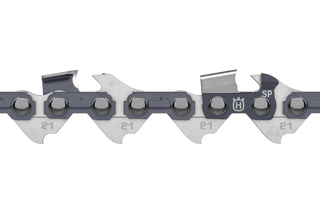

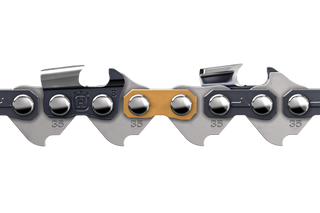

Example, X‑CUT™ SP33G

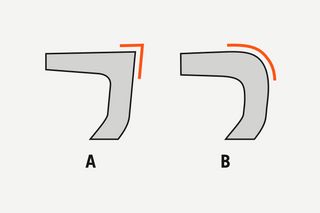

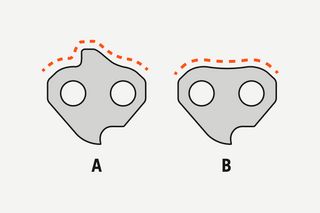

The C stands for Chisel. The chain has square corner cutters, which provides superior cutting efficiency. This cutter profile is only recommended for professional users working in clean conditions. (Figure A)

The S stands for Semi-Chisel. The corners are rounded, which eases maintenance and have good stay-sharp properties. This cutter profile is more forgiving regarding filing angles and is less sensitive to dirt. Suitable for all users. (Figure B)

Example, X‑CUT™ SP33G

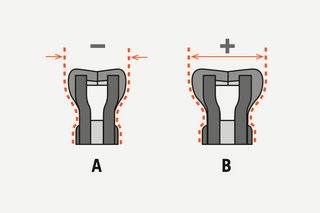

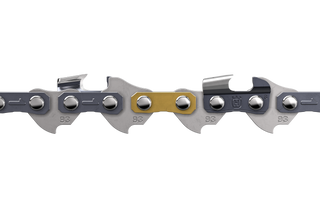

P – Pixel

Some of our X-CUT and X-Precision chains have a P in their name, and the P stands for Pixel. Pixel chain and guide bars, with thinner chassis, are low in weight and provide a narrow cut – resulting in enhanced cutting efficiency. This chain type is only to be used with the corresponding Pixel guide bars. (Figure A)

No letter – Standard

However, it is more common that there is no letter after the C or S in the chain name. That chain type is a tougher, broader cutting chain, with standard chassis enabling more rigid and robust chains and bars. (Figure B)

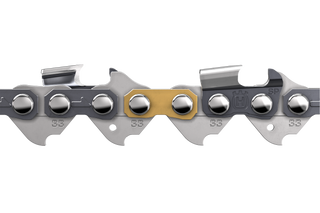

Example, X‑CUT™ SP33G

The first digit after the letters tells the pitch size. Mini chains have low profile cutters, smaller drive links and are suitable for smaller chain saws.

1 = 1/4” mini

2 = .325” mini

3 = .325”

8 = 3/8

9 = 3/8” mini

The pitch of the chain must match the pitch of the guide bar and the drive sprocket on your chainsaw.